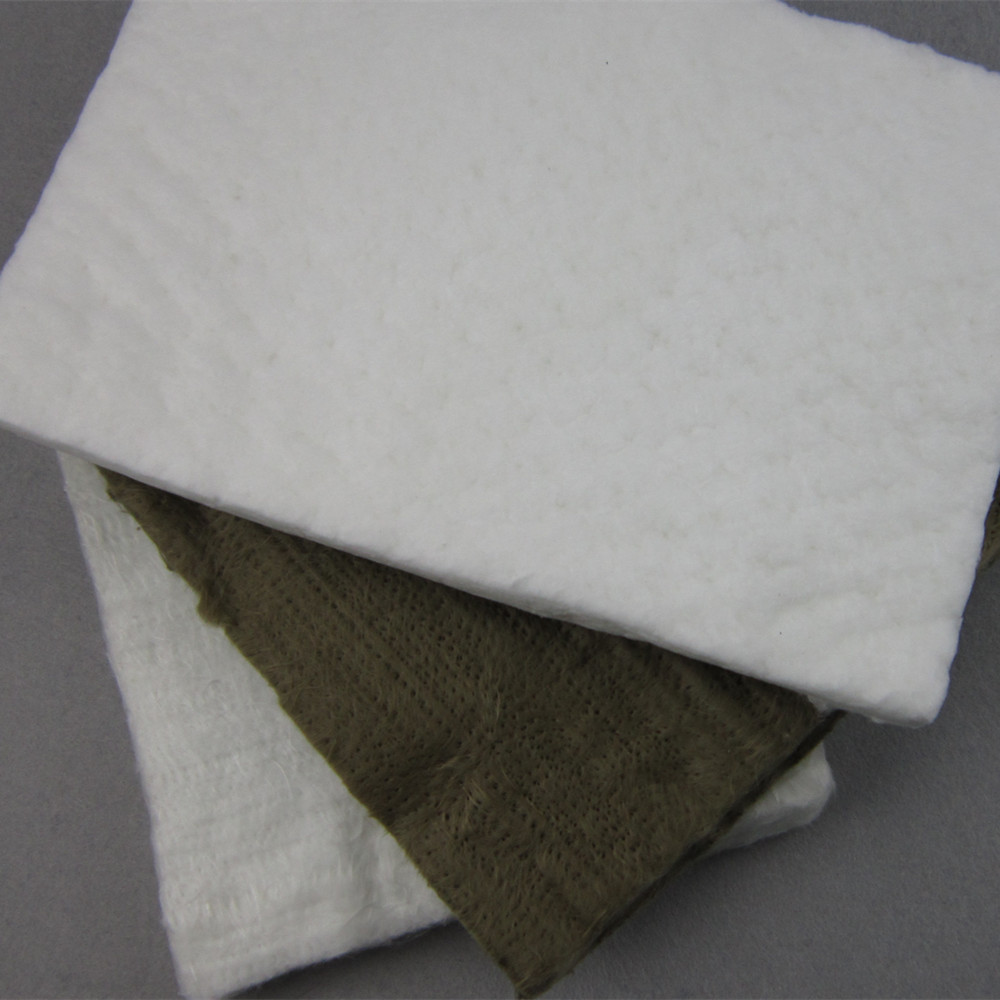

Stosowanie maty igłowej krzemionkowej w układach wydechowych i tłumikach ma kilka zalet ze względu na jej unikalne właściwości. Oto kilka kluczowych powodów jego stosowania:

Odporność na wysoką temperaturę: Mata igłowa z krzemionki może wytrzymać ekstremalne temperatury, dzięki czemu idealnie nadaje się do zastosowań w układach wydechowych, gdzie głównym problemem jest ciepło. Może zachować integralność strukturalną i wydajność nawet w warunkach wysokiej temperatury.

Izolacja termiczna: Mata zapewnia doskonałą izolację termiczną, pomagając zmniejszyć przenikanie ciepła do otaczających elementów. Pomaga to w utrzymaniu optymalnej temperatury roboczej, co może zwiększyć ogólną wydajność i trwałość systemu.

Pochłanianie dźwięku: Mata igłowa z krzemionki ma właściwości pochłaniające dźwięk, które mogą pomóc zmniejszyć poziom hałasu w układach wydechowych. Jest to szczególnie korzystne w przypadku tłumików, gdzie kluczowym wymaganiem jest redukcja hałasu.

Lekki: Lekka mata igłowa z krzemionki ułatwia obsługę i instalację. Może to przyczynić się do ogólnego zmniejszenia masy pojazdu lub wyposażenia, zwiększając wydajność.

Odporność chemiczna: Krzemionka jest odporna na wiele chemikaliów i czynników środowiskowych, zapewniając trwałość i niezawodność w trudnych warunkach. Ta odporność pomaga chronić układ wydechowy przed substancjami żrącymi, które mogą się w nim znajdować.

Niepalny: Jako materiał niepalny, mata igłowa z krzemionki zapewnia dodatkowe bezpieczeństwo, minimalizując ryzyko zagrożenia pożarowego w zastosowaniach wysokotemperaturowych.

Wszechstronność: Matę igłową z krzemionki można łatwo przyciąć i ukształtować tak, aby pasowała do różnych konfiguracji układu wydechowego, co czyni ją uniwersalnym rozwiązaniem dla różnych projektów.

Trwałość: Materiał jest trwały i wytrzymuje obciążenia mechaniczne, zapewniając długą żywotność, co zmniejsza potrzebę częstych wymian.

Podsumowując, krzemionkowa mata igłowato skuteczne rozwiązanie dla układów wydechowych i tłumików, zapewniające izolację termiczną, pochłanianie dźwięku oraz odporność na wysokie temperatury i chemikalia, co przyczynia się do poprawy wydajności i trwałości.