Zrozumienie mat igłowych z włókna szklanego: zastosowania, właściwości i zalety

Wprowadzenie do mat igłowych z włókna szklanego

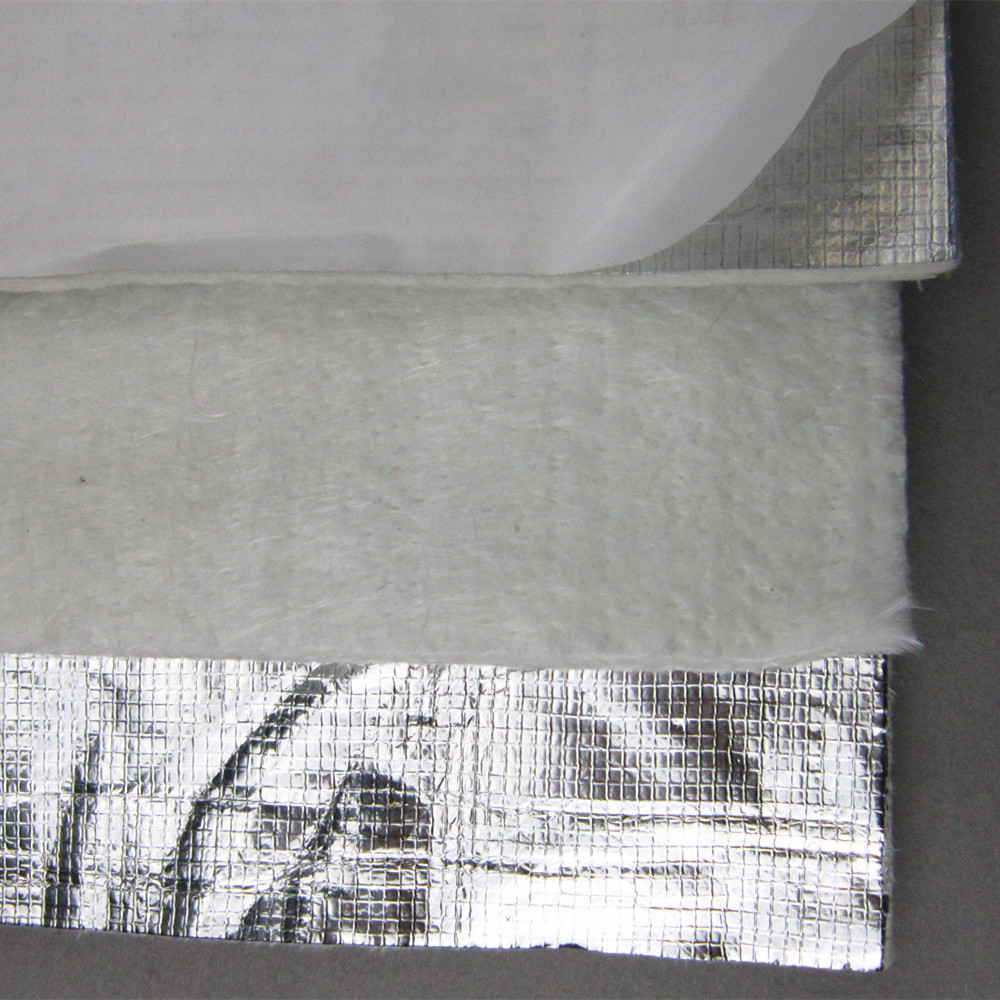

Maty igłowe z włókna szklanego to zaawansowane materiały składające się z włókniny, losowo zorientowanych włókien szklanych, które są łączone ze sobą w procesie igłowania. Technika ta polega na wielokrotnym nakłuwaniu maty kolczastymi igłami, splataniu włókien w celu utworzenia spójnej, trwałej maty. Maty te są znane ze swoich wyjątkowych właściwości i są wykorzystywane w różnych gałęziach przemysłu.

Właściwości mat igłowych z włókna szklanego

Odporność na wysoką temperaturę: Maty igłowe z włókna szklanego wytrzymują wysokie temperatury, dzięki czemu idealnie nadają się do zastosowań izolacyjnych w środowiskach narażonych na ekstremalne temperatury.

Odporność chemiczna: Materiał z włókna szklanego jest odporny na szeroką gamę chemikaliów, zapewniając trwałość i długowieczność w trudnych warunkach.

Niska przewodność cieplna: Maty te zapewniają skuteczną izolację termiczną poprzez zmniejszenie przenikania ciepła, co jest niezbędne dla efektywności energetycznej w procesach przemysłowych.

Wytrzymałość mechaniczna: Proces igłowania nadaje matie znaczną wytrzymałość mechaniczną, czyniąc ją sprężystą pod wpływem naprężeń fizycznych.

Odporność ogniowa: Maty z włókna szklanego są z natury ognioodporne, co zapewnia dodatkowe bezpieczeństwo i ochronę w różnych zastosowaniach.

Zastosowania mat igłowych z włókna szklanego

Izolacja przemysłowa:

Konstrukcja:

Przemysł motoryzacyjny:

Przemysł lotniczy:

Zastosowania morskie:

Wniosek

Maty igłowe z włókna szklanegooferują wszechstronne i skuteczne rozwiązanie do szerokiego zakresu zastosowań, dzięki swoim niezwykłym właściwościom, takim jak odporność na wysoką temperaturę i chemikalia, niska przewodność cieplna i wytrzymałość mechaniczna. Niezależnie od tego, czy są to zastosowania przemysłowe, budowlane, motoryzacyjne, lotnicze czy morskie, maty te zapewniają znaczne korzyści, zwiększając wydajność, bezpieczeństwo i efektywność energetyczną.