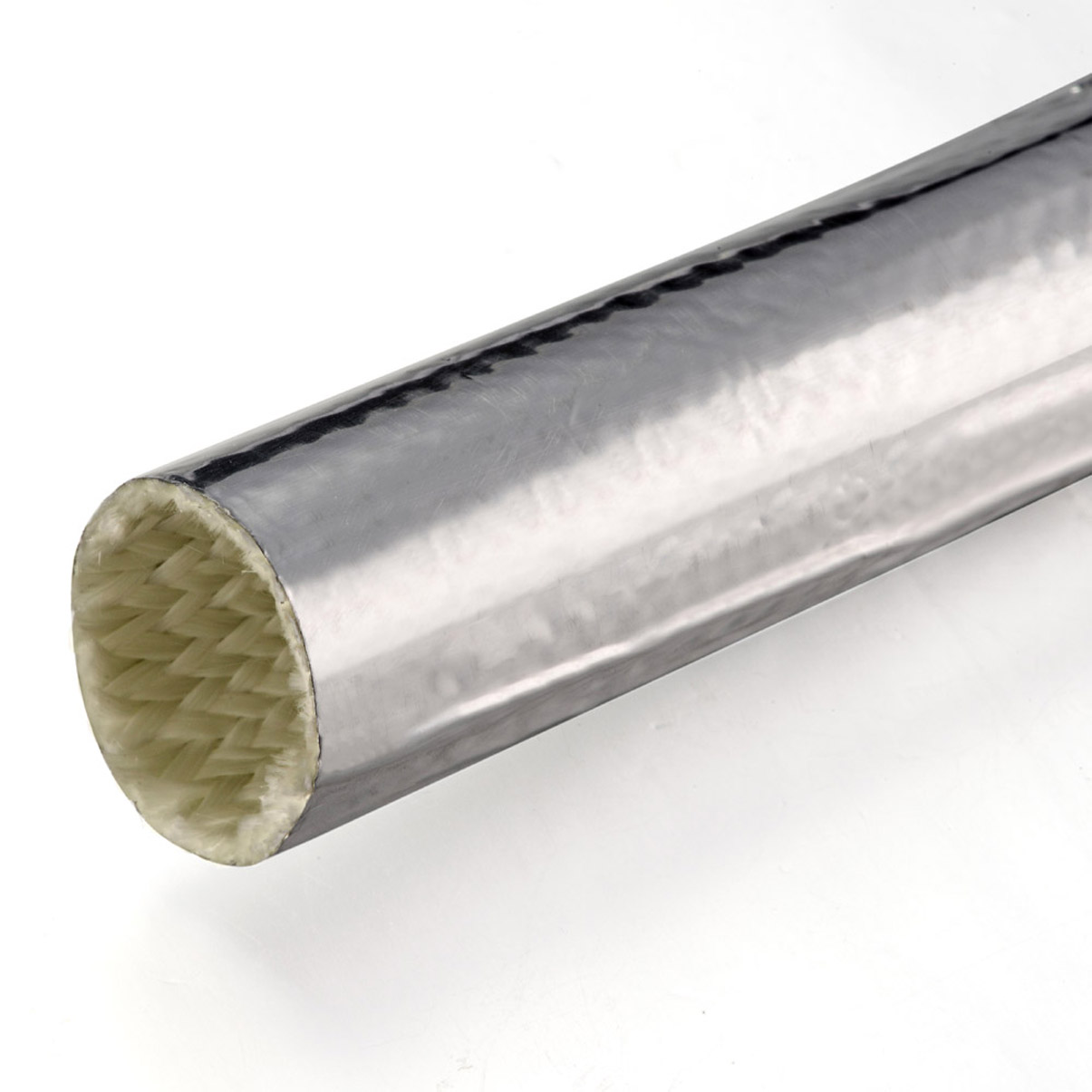

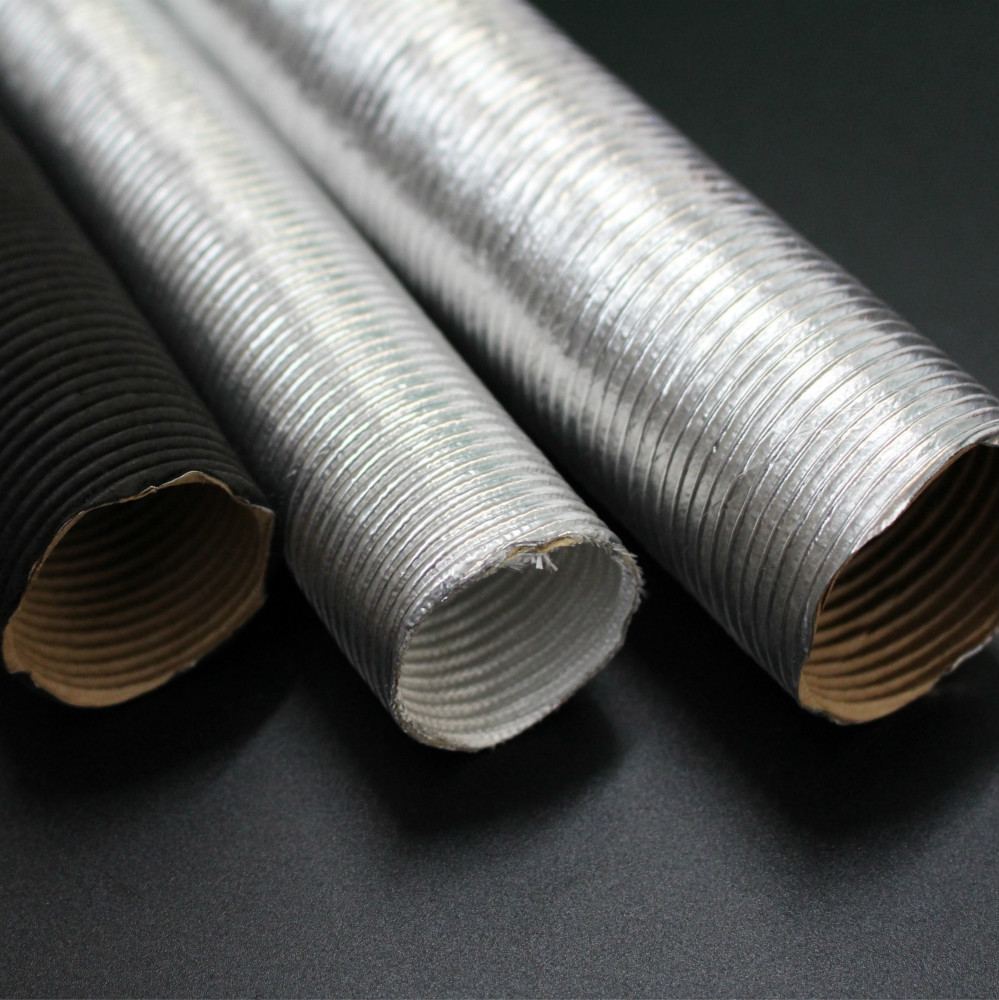

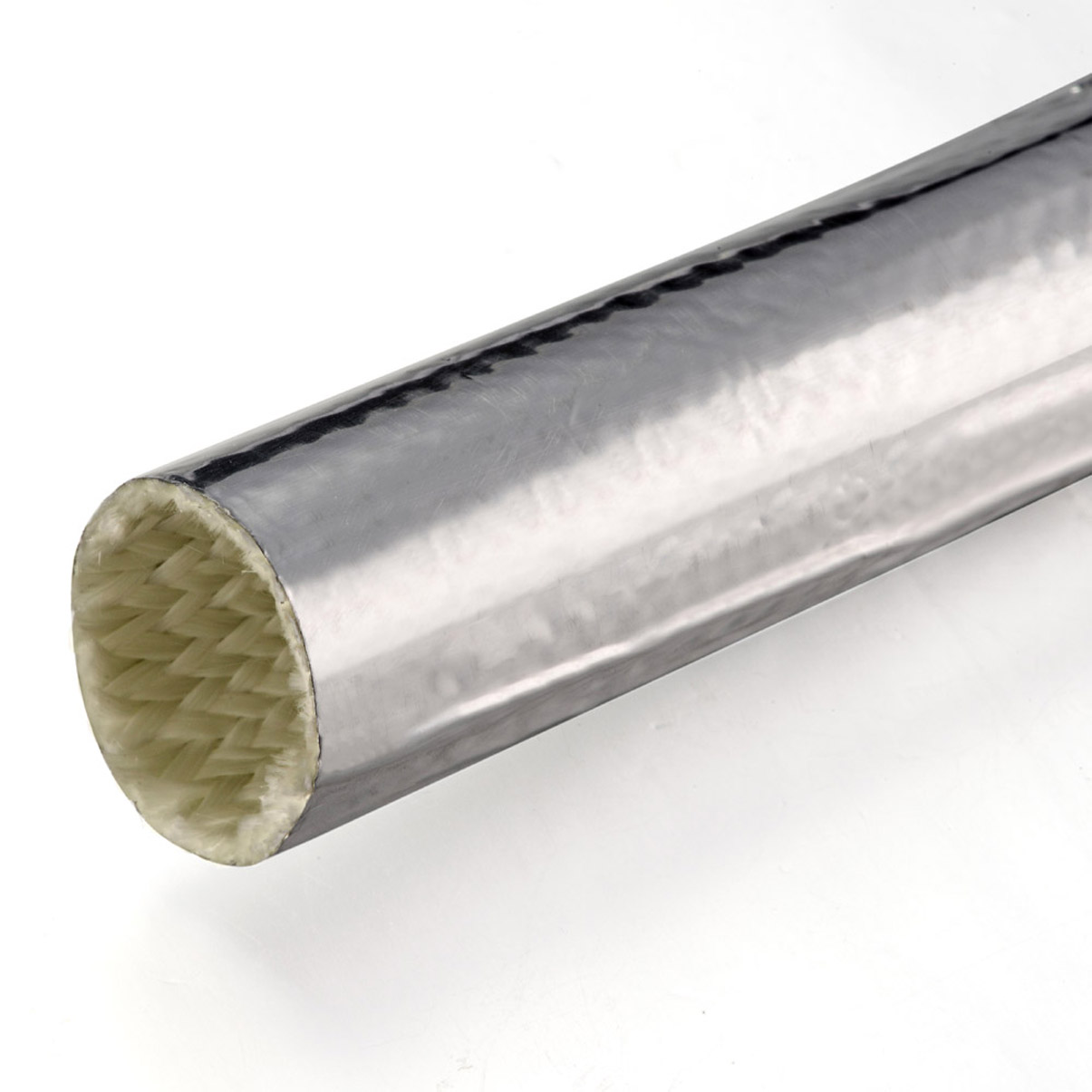

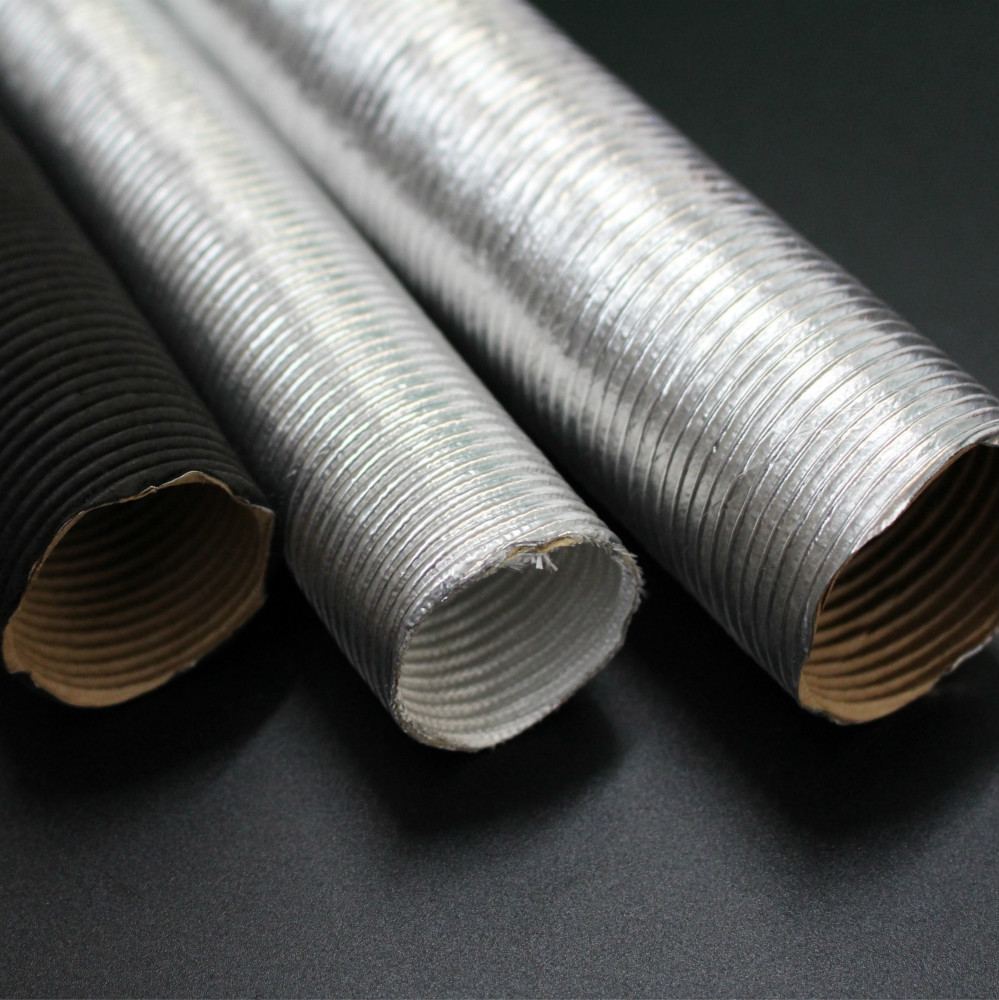

Aluminiowe rurki osłony termicznej to rodzaj izolacji ochronnej powszechnie stosowanej w różnych gałęziach przemysłu, gdzie problemem są wysokie temperatury lub narażenie na źródła ciepła. Rury wykonane są z aluminium lub materiałów na jego bazie, które zapewniają doskonałą odporność na ciepło, odbijając znaczną ilość ciepła z dala od wrażliwych komponentów. Niektóre z głównych zastosowań aluminiowych rur osłonowych obejmują:

1. Motoryzacja i sporty motorowe

-

Ochrona przewodów i węży: W pojazdach o wysokich osiągach, szczególnie podczas wyścigów, aluminiowe rurki osłony termicznej służą do ochrony przewodów, przewodów paliwowych, przewodów hamulcowych i innych elementów przed nadmiernym ciepłem wytwarzanym przez silnik, układ wydechowy lub turbosprężarki. Pomaga zapobiegać uszkodzeniom spowodowanym ciepłem i zapewnia prawidłowe działanie najważniejszych części.

-

Układy wydechowe i turbosprężarki: Rury osłony termicznej można stosować do owijania układów wydechowych lub rur turbosprężarki w celu utrzymania optymalnych warunków temperaturowych i zapobiegania uszkodzeniu pobliskich podzespołów przez ciepło.

2. Przestrzeń kosmiczna

-

Elementy silnika: W samolotach aluminiowe rurki osłony termicznej służą do ochrony kabli, przewodów i wrażliwych elementów przed ekstremalnym ciepłem, które może być generowane przez silniki lub układy wydechowe.

-

Ochrona termiczna: W przypadku samolotów szybkich ten typ rur zapewnia izolację termiczną, aby zapobiec przegrzaniu krytycznych układów narażonych na przepływ powietrza o wysokiej temperaturze.

3. Sprzęt przemysłowy

-

Ochrona maszyn: W branżach takich jak produkcja i wytwarzanie energii aluminiowe rurki osłony termicznej służą do ochrony kabli, węży i podzespołów przed gorącymi powierzchniami, takimi jak silniki, turbiny lub otwory wentylacyjne.

-

Bezpieczeństwo i trwałość: Służy do utrzymania trwałości kabli i przewodów poprzez ekranowanie ich przed ciepłem, które może spowodować uszkodzenie izolacji lub awarie elektryczne.

4. Zastosowania morskie

-

Ochrona układów silnika: W środowisku morskim aluminiowe rurki osłony termicznej służą do ochrony krytycznych układów, takich jak przewody paliwowe i elementy elektryczne, przed ciepłem silnika i narażeniem na słoną wodę, która może powodować korozję.

-

Osłona termiczna spalin: Rury można również stosować wokół układów wydechowych łodzi, aby pomóc w zarządzaniu wysokimi temperaturami.

5. Elektronika i panele słoneczne

-

Zarządzanie ciepłem: W wrażliwych urządzeniach elektronicznych, w tym w systemach paneli słonecznych, aluminiowe osłony termiczne pomagają zarządzać gromadzeniem się ciepła, odbijając ciepło od urządzenia, zapobiegając przegrzaniu i poprawiając wydajność.

6. Budownictwo i HVAC

-

Izolacja termiczna: Aluminiowe rury osłonowe są czasami stosowane w budownictwie, szczególnie do izolowania rur lub kanałów w obszarach narażonych na działanie wysokich temperatur, np. w pobliżu kotłów lub pieców.

Właściwości aluminiowych rurek osłony termicznej:

-

Wysoki współczynnik odbicia ciepła: Aluminium odbija do 80-90% ciepła promieniowania, dzięki czemu stanowi skuteczną osłonę przed przenikaniem ciepła.

-

Lekki i trwały: Aluminium jest zarówno lekkie, jak i odporne na korozję, co czyni go idealnym do wielu zastosowań, w których liczy się przestrzeń i waga.

-

Elastyczny i łatwy w montażu: Rury są często projektowane jako elastyczne, co ułatwia montaż wokół rur, kabli lub innych elementów.

Podsumowując, aluminiowe rurki osłony termicznej są stosowane w sytuacjach, w których istnieje potrzeba ochrony wrażliwych komponentów przed wysokimi temperaturami, albo poprzez odbijanie ciepła, albo poprzez zapewnienie bariery fizycznej.